Describe How a Furniture Manufacturer Would Use Rapid Prototyping

Using rapid prototyping you can have your part or product designed and tested in a short timeframe. Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design data.

Web Form Agile Methodology Rapid Prototyping Sheet Metal Fabrication Injection Moulding

Place a timer 10 minutes and advise each person to visualize demonstrate how that problem might be solved.

. With this approach 3-dimensional prototypes of a product or feature are created and tested to optimize characteristics like shape size and overall usability. Its milled out on a CNC machine or built up with a 3D printing stereolithography system. Thus furniture designers can convey their ideas and implement them prior to finalization very quickly.

The rapid prototyping process includes using data that is processed into a 3D model. In use for more than 20 years among the elite of manufacturing companies rapid prototyping continues to prove itself by empowering rapid product innovation. The prototype can be tested before the product or part is manufactured in larger quantities.

Rapid Prototyping is the process by which a manufacturer creates a 3D replica of a product from a 2D computer design. With rapid prototyping the differences between techniques make each one best suited for different applications. Ie they are now being used for.

We use RevitInventor building design software to model document and communicate our designs at every stage of your project. Placing multiple layers of materials in. This allows you to have a full-scale model ready to determine whether it meets your requirement or not.

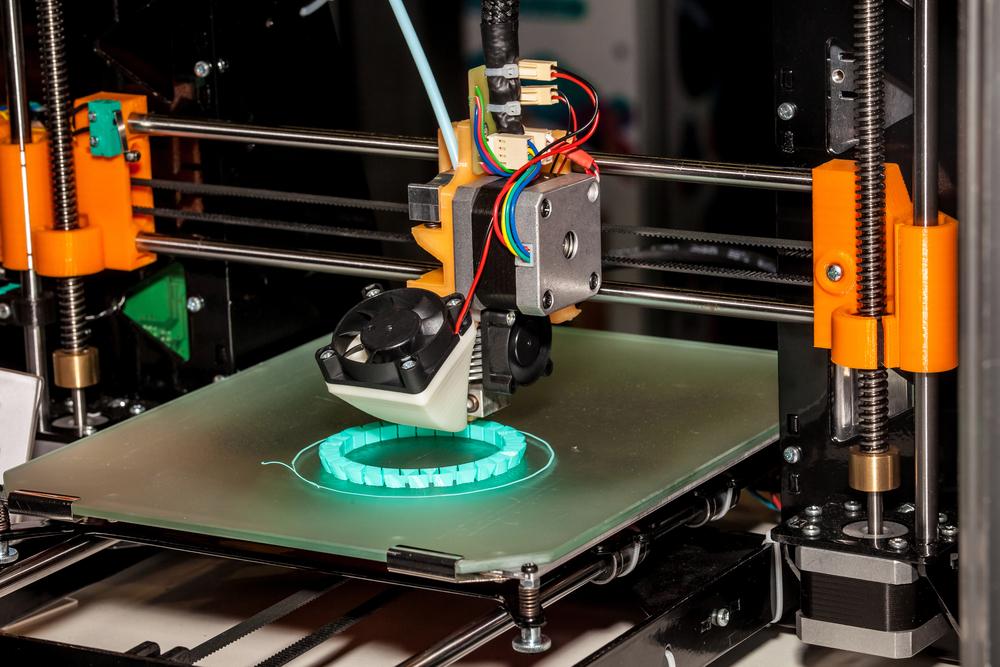

Historically this term has referred to the use of additive manufacturing to create the part. Rapid prototyping works by short cycles to adjust fast the overall design. The 3D printer with 3DP is applying the standard inkjet technology by placing the liquid junction in the thin layer of.

Traditionally each physical prototype would require a new design to be outsourced to a manufacturer to be made with subtractive eg milling cutting or moldingcasting processes. Construction of the part or assembly is usually done using 3D printing or additive layer manufacturing technology. All these processes are created using computer-aided design and 3D scanning which are necessary for printing of 3D objects.

The primary factors to consider are. It Saves Big Bucks and Time. This process is an additive process unlike the traditional subtractive processes of machining 1.

Rapid prototyping is the fast fabrication of a physical part model or assembly using 3D computer aided design CAD. Rapid prototyping is an agile strategy used throughout the product development process. Patchwork prototyping is a type of rapid prototyping that involves the use of open-source software and was a part of an incredible study at.

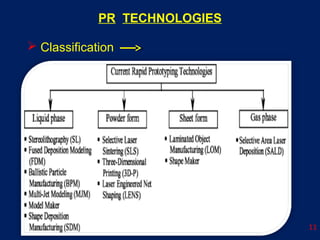

The first methods for rapid prototyping became available in the mid 1980s and were used to produce. Currently in the market rapid prototyping technology is classified into 3DP FDM Fused Deposition ModelingSLA Steroligograph Apparatus SLS Selective Laser Sintering DLP Digital Light Procession and UV Prototyping Technology. Using rapid prototyping to manufacture parts to test for component fit and function can help get your product to market faster than your competition.

Our prototyping process takes into account our clients need take the prototype to market. Expected product quality a rough design or functioning prototype Product fidelity desired look and feel of the manufactured item Part complexity for greater complexity more precise rapid prototyping tools should be. It is capable of sourcing from a large variety of plastic and metal and some methods allow the addition of different materials to create composites that feature enhanced tolerances.

It is more expensive per part then a hard-tooled injection molded piece but it doesnt take a quarter to three. Where the design closely matches the proposed finished product it is said to be a high fidelity prototype as opposed to a. Rapid prototyping creates product simulations for testing and.

With this advancement in technology rapid prototyping has found its way in the manufacturing of many custom-made parts prototypes. Adjustments in design materials size shape assembly color manufacturability and strength can be made following the results of your testing and analysis. If its all good then you can approve the full production of the product and move on to develop more products.

Doing is the best kind of thinking. The visibility that rapid prototyping ensures helps receive an early concept validation from the team investors and end-users. This leads to a seamless move from prototyping to full production.

The basic process of rapid prototyping techniques is the use of a CAD file model that is divided by software into a stack of thin slices. Rapid prototyping employs a few technologies from CAD design software to manufacturing process es to create a series of prototypes. In much the same way designers in the digital world have adopted rapid prototyping as a quick and cost-effective way to build and test a working version of their product.

Its design and engineering process allows you to be innovative and creative. With rapid prototyping you use a completely different process. In manufacturing rapid prototyping is used to create a 3D model of a product or a single part of a product.

We have metal workers wood workers seamstress and more. Rapid prototyping also called three-dimensional impression helps companies grow ideas into unique products. The creation of the part model or assembly is usually completed using additive manufacturing or more commonly known as 3D printing.

Techniques to quickly fabricate a scale model of a physical part or assembly. Prototyping Helps You Think. Provide each person with paper and a pen and describe the problem that is to be solved.

Rapid prototyping service in manufacturing it is cost-effective and reduces the time spent in developing patterns molds and also eliminates the cost of bringing in specialised tools. We can use prototypes to think to answer questions to communicate and to inform decisions. With this data a 3D printer adds the chosen material to recreate the original product.

You can design and fabricate parts using 3D printing techniques. With that out of the way lets move on to why prototyping can be used for far more than just usability testing. The construction of the prototype involves additive manufacturing ie.

Now advances in 3D printing technology have enabled prototypes to go beyond the form and fit of finished products and encompass higher level criteria such as functionality and performance. The term is falling out of favor to describe all additive manufacturing technologies because they are seen as being able to do more than just prototyping. It is a completely different path that delivers an almost identical result.

You will use the same printing equipment and CAD software to produce various geometries.

![]()

3d Printing And Modeling Flat Icons Set Stock Vector Illustration Of Layout Making 41828060

U S And China To Ratify Paris Climate Change Agreement Https Goo Gl 47d30u Prototype Design Industrial Design Style Design Thinking Process

China Abs Pvc Pa66 Gf Pc Hdpe Pet Rapid Prototyping Plastic Prototypes Parts Mold Mould Molding Moulding Molds Moulds China Plastic Mold Injection Mold

What Are The Different Software Applications Used In Rapid Prototyping

The Difference Between Rapid Prototyping And 3d Printing Dienamics

Classification Of Rapid Prototyping Processes Some Of The Important Download Scientific Diagram

Rapid Prototyping 5 Ways To Level Up Furniture Manufacturing

Best Plastic Rapid Prototyping Machine Youtube

How Rapid Prototyping Helps You Design And Develop Products Quickly Technosoft Engineering

Rapid Control Prototyping Png Images Pngwing

Rapid Prototyping Materials Market Growth Trends Covid 19 Impact And Forecasts 2022 2027

Rapid Prototyping Services 3d Printing Prototype Parts Manufacturing

Rapid Prototyping And 3d Printing A Perfect Match

Rapid Prototyping 5 Ultimate Ways To Use It In Furniture Production

Effective Techniques For Rapid Prototyping Usability Geek Rapid Prototyping Interaction Design Foundation Prototype